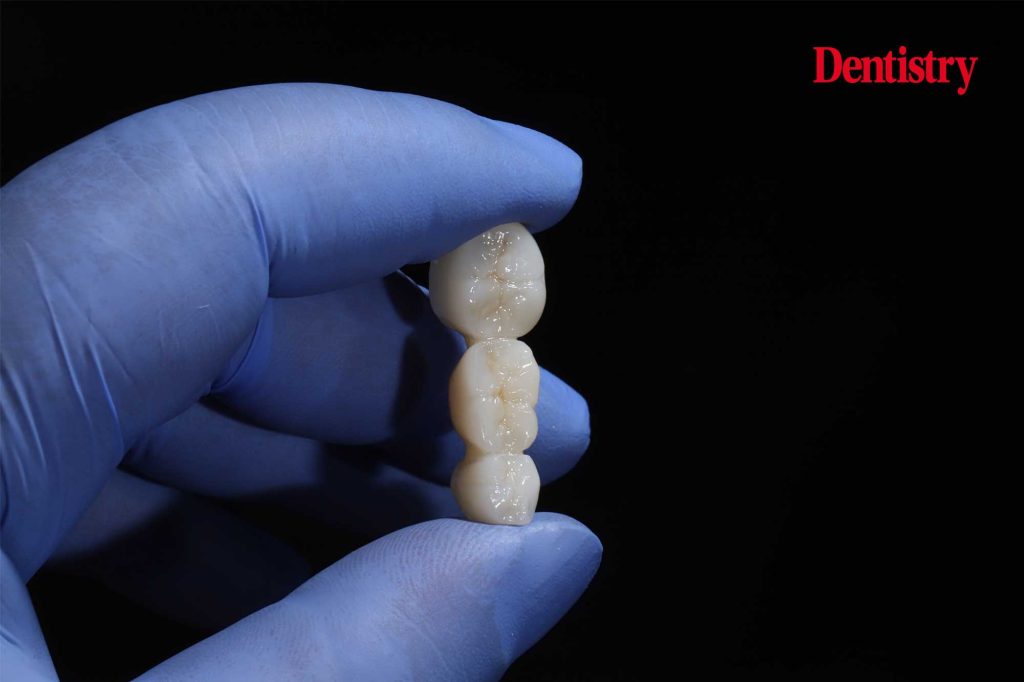

Permanent crowns, bridges and veneers can now be 3D printed in zirconia at patients’ chairside within the same day.

Researchers at the University of Texas at Dallas are working to make newly-developed technology commercially available which will allow all-ceramic restorations to be rapidly 3D printed in dental practices.

Dr Majid Minary is a professor of mechanical engineering in the Erik Jonsson School of Engineering and Computer Science. He said: ‘Because the crowns can be custom-printed for each patient on the same day, this approach offers greater personalisation, faster treatment and the convenience of receiving a permanent restoration in a single visit.’

Though same-day zirconia restorations are already widely available, they are exclusively creating through milling. This approach presents limitations in design complexity and risks for micro-cracking during milling or sintering.

The researchers said that 3D printing offers better customisation and stronger colour matching. It is also a more efficient manufacturing process, reducing costs and waste.

Crowns made through same-day 3D printing have also been made available previously, but they have exclusively been fabricated in ceramic resins that are not as strong as zirconia.

How are 3D-printed zirconia restorations made?

The researchers explained their approach to 3D printing zirconia restorations in Ceramics International. One challenge presented by this method was the need for lengthy processing post-printing.

After printing, the zirconia restorations require both debinding and sintering. Dr Minary said: ‘Debinding has been the bottleneck in the process. It must be done very slowly. If you speed it up, the polymer being burned off turns into gas, and if that gas cannot escape, the crown may crack or fracture.

‘A debinding time of 20 to 100 hours is not practical for same-day dental service. As a result, 3D-printed permanent zirconia restorations are not yet commercially available.’

The team solved this pitfall by reducing debinding time to less than 30 minutes. Dr Minary concluded: ‘With our technology, if a practitioner wants to offer a 3D-printed zirconia crown chairside, they could provide it to a patient within just a few hours.’

This method will require clinical validation and regulatory approval before becoming commercially available.

Follow Dentistry.co.uk on Instagram to keep up with all the latest dental news and trends.