Zirkonzahn presents a restoration case using new zirconia for primary structures with extremely high flexural strength.

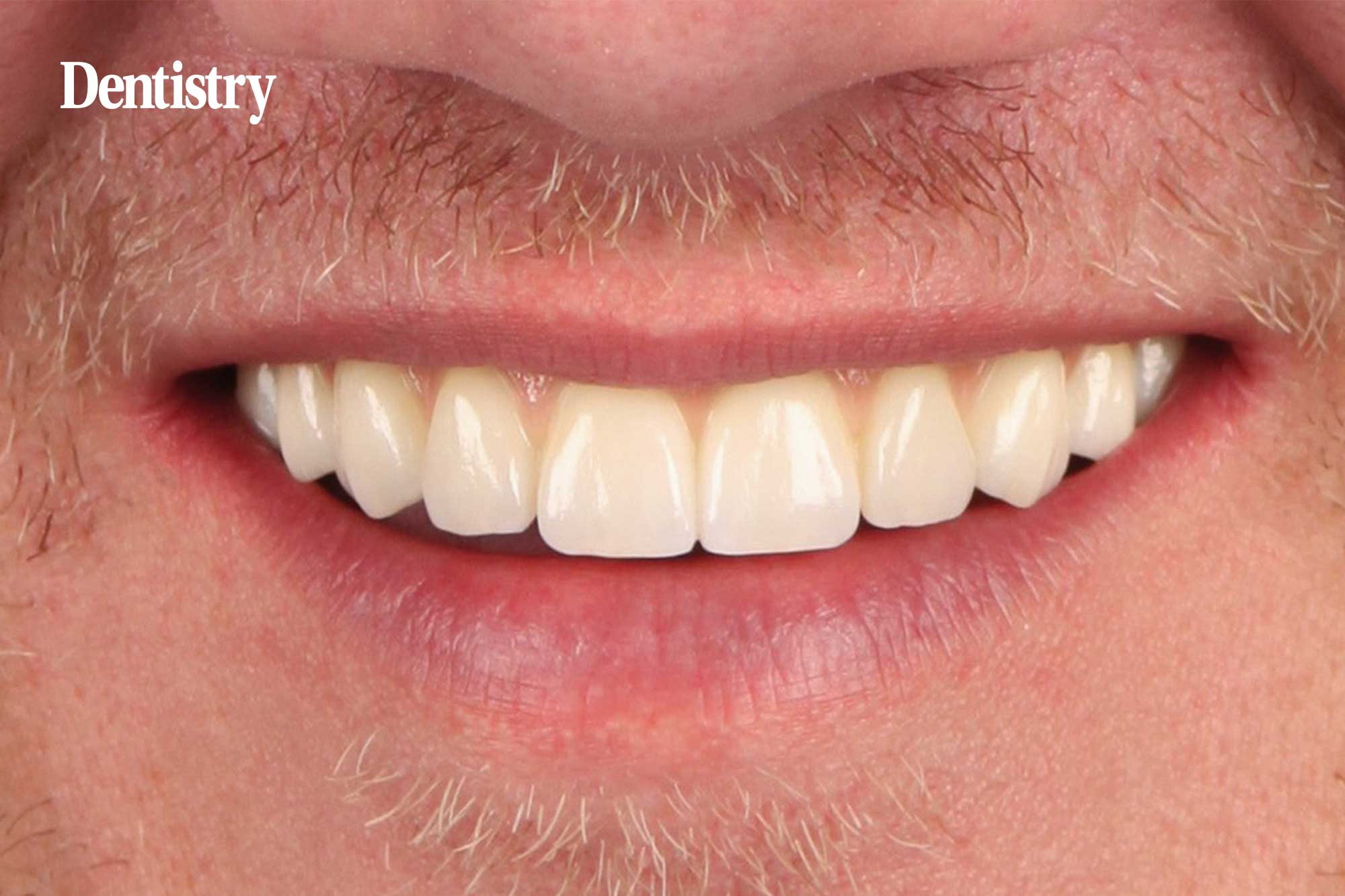

A male patient presented with a previous Pekkton-PMMA immediate temporary restoration supported by four implants in each jaw, seeking a stable and highly aesthetic definitive solution. Following comprehensive diagnostic assessment, the techno-clinical team decided to provide full-arch zirconia restorations for both the maxilla and mandible.

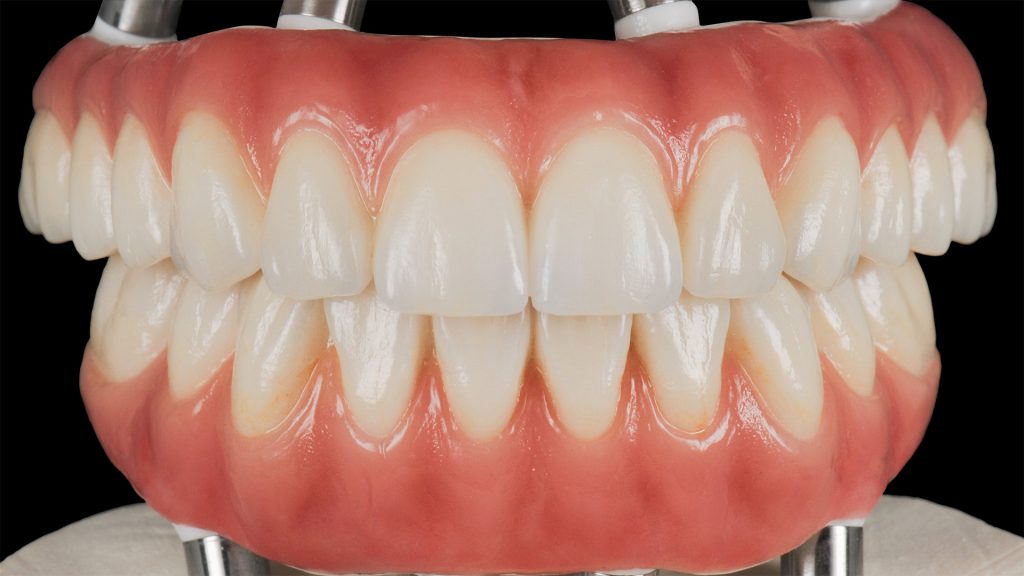

The definitive prostheses were designed with a superstructure in Prettau 2 Dispersive zirconia to ensure optimal aesthetics and natural translucency, supported by a substructure in ICE Plus zirconia to ensure strength and long-term stability.

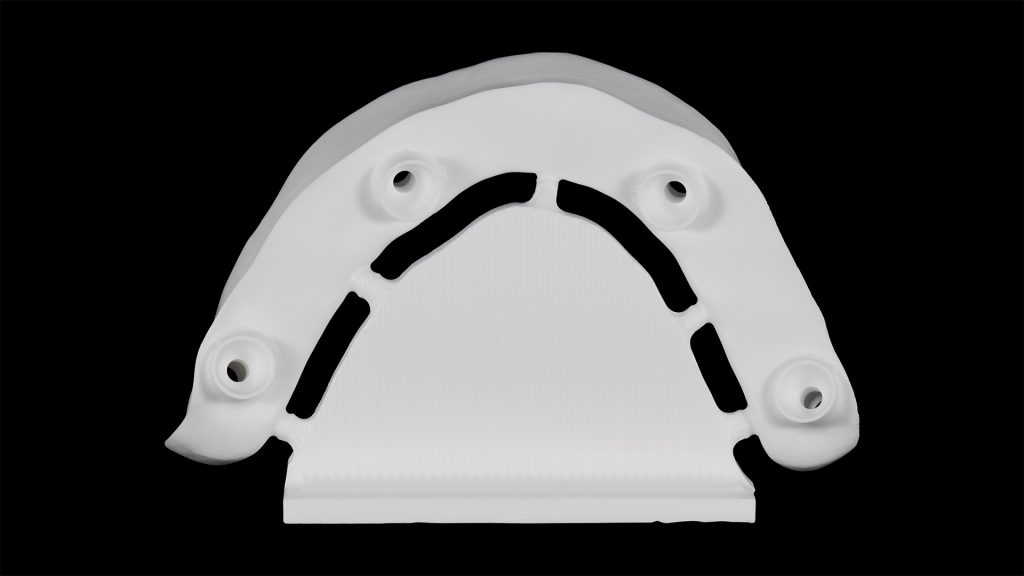

The decision to use ICE Plus zirconia (Zirkonzahn) was based on its favorable mechanical properties for high-load, implant-supported rehabilitations or large-span bridges. Indeed, this material, which is ideal for reduced frameworks, exhibits a flexural strength of approximately 1,650 MPa (without HIP – Hot Isostatic Pressing) or up to 1,900 MPa (with HIP treatment).

Additionally, using Fusion Powder (Zirkonzahn), ICE Plus can serve as a primary structure (pictures 1 and 2) to which a secondary zirconia framework may be bonded (pictures 3 and 4), representing a significant advancement in the fabrication of aesthetically demanding, fully ceramic hybrid restorations without any metal components.

Creating the restoration

The restoration was produced through a structured digital workflow. First, implant positions were acquired using photogrammetry technology, while the soft tissues were captured with an intraoral scanner, followed by the definition of the smile design.

Super and substructures were then printed and tried in the patient’s mouth. After both the dentist and the patient positively evaluated the try-in, the digital design of the upper and lower full arches in Prettau 2 Dispersive zirconia and the substructures in ICE Plus zirconia was finalised.

All structures were subsequently milled using Zirkonzahn’s M1 Wet Heavy Metal and M2 Teleskoper milling units, then sintered. Following sintering, the superstructures were bonded to the substructures with Fusion Powder.

In the anterior region, a minimal ceramic layering was applied to the superstructures with ICE Ceramics, while the posterior teeth were individualised with ICE Stains 3D by Enrico Steger; the gingiva was also stratified with ceramics.

For more information visit www.zirkonzahn.com or meet Zirkonzahn at the ADI Member’s National Forum in London on 22 November 2025.

Finally, the restoration was polished (pictures 5 to 7) and delivered to the dentist for insertion in the patient’s mouth.

This article is sponsored by Zirkonzahn.